Main Components of Solar Panel

Solar panels are making their name in the world in the recent years. They have been utilized by people almost in every region of the world. Solar panels are used but there arose a question here that what is this thing? How it is manufactured? What things are used in it which convert the solar light into usable electricity.

In this blog, we will discuss the different and main components of solar panel. A solar panel is generally made of six components which are listed below:

Solar Photovoltaic Cells

Solar photovoltaic cells, commonly referred as solar cells are the devices or cells that convert light energy directly into electricity. These cells are the building blocks of solar panels to generate electricity. Without them, a solar panel cannot be manufactured.

Working

The term used for the working of solar cells is ”Photovoltaic Effect”. When sunlight falls on a solar cell, it excites its electrons which flow as a result, thus generating electricity.

Composition

Most solar cells are made of semi-conductor materials such as silicon. Silicon solar cells are mostly used due to their availability, efficiency and stability. Other materials such as cadmium telluride (CdTe), copper indium gallium selenide (CIGS), and perovskite are also being researched and developed for use in solar cell applications.

Types of Solar Cells

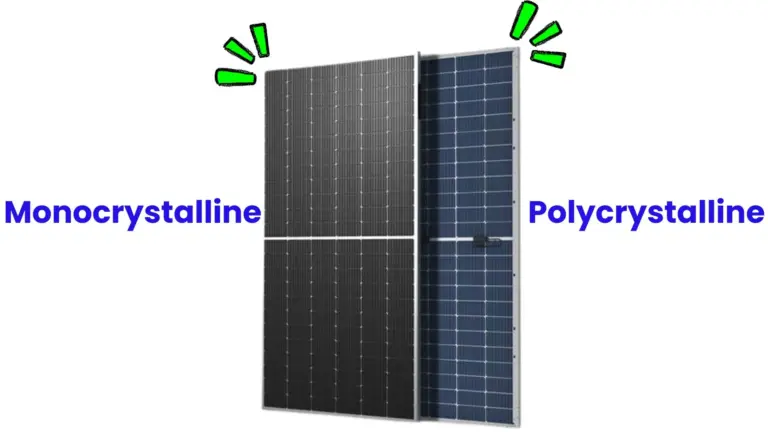

Solar cells are of three types:

Monocrystalline cells: These cells are made from a single crystal of silicon and typically have higher efficiency and durability compared to other types.

Polycrystalline cells: Made from silicon crystals melted together, polycrystalline cells are less expensive to produce but may have slightly lower efficiency compared to monocrystalline cells.

Thin-Film cells: These cells are made by depositing thin layers of photovoltaic material onto a substrate. Thin-film cells are flexible and can be used in applications where rigid panels are not suitable.

Aluminum Frame

Solar panel frames are the structures that provide protection and support to the solar photovoltaic modules. Aluminum is the most commonly used material for solar panel frames due to its excellent strength-to-weight ratio and resistance to corrosion. This makes it ideal for withstanding outdoor conditions and ensuring the longevity of the solar panel system.

Solar panel frames are designed to provide structural integrity to the solar modules while minimizing weight. Aluminum frames are often coated with a protective finish to enhance their durability and resistance to environmental factors such as moisture, UV radiation, and temperature fluctuations.

Well-designed frames with proper ventilation and drainage features can help optimize airflow around the panels, reducing heat buildup and improving overall efficiency.

Transparent Glass

Solar panel transparent glass, also known as solar glass or photovoltaic (PV) glass, is a specialized type of glass used in the construction of solar photovoltaic modules. This glass serves several important functions in the solar panel structure:

Light Transmission

The primary function of transparent glass is to allow sunlight to pass through the solar cells. It must have high transparency to ensure that more light enters the solar panel for effective energy production.

Protection

Transparent glass provides protection to the sensitive PV cells and other components of the solar panel from environmental factors such as moisture, dust, debris, and temperature fluctuations.

Encapsulant

Encapsulant is a crucial component in solar panels that serves to protect and insulate the photovoltaic (PV) cells and other internal components from environmental factors and mechanical stress.

Protection

One of the primary functions of encapsulant is to provide protection to the sensitive PV cells against various environmental factors. It acts as a barrier, preventing water ingress and corrosion, which could otherwise damage the solar cells and reduce their efficiency over time.

Insulation

Encapsulant also serves as an electrical insulator, helping to prevent short circuits and electrical arcing between the conductive components within the solar panel. This insulation is essential for maintaining the electrical integrity and safety of the solar panel system.

Composition

Common materials used for encapsulant include ethylene-vinyl acetate (EVA) and polyvinyl butyral (PVB). These materials are chosen for their excellent electrical insulation properties, adhesion strength, optical clarity, and resistance to UV radiation and weathering.

Polymer Backsheet

The polymer backsheet is an essential component of a solar panel, serving as the rear protective layer that shields the photovoltaic (PV) cells from any damage.

Composition

solar panel backsheets were made of materials such as Tedlar (polyvinyl fluoride, PVF) or polyester (polyethylene terephthalate, PET). However, modern solar panels increasingly use polymer backsheets made from ethylene-vinyl acetate (EVA) or polyvinylidene fluoride (PVDF) due to their superior properties.

Protection

The polymer backsheet provides electrical insulation to the solar cells, helping to prevent short circuits and electrical arcing. This insulation is crucial for maintaining the electrical integrity and safety of the solar panel system.

Durability

Polymer backsheets are designed to withstand prolonged exposure to outdoor conditions, including temperature fluctuations, humidity, and mechanical stress. They are formulated to be resistant to UV degradation, weathering, and chemical exposure, ensuring the long-term performance and reliability of the solar panel.

Junction Box

The junction box is an essential component of a solar panel, serving as a central point for electrical connections and providing protection for the wiring and components within the panel. It is typically located on the back of the solar panel, near the top or bottom edge.

Function

The primary function of the junction box is to serve as a hub for electrical connections between the individual solar cells or strings within the solar panel. It connects the positive and negative terminals of the solar cells or strings to form a complete electrical circuit.

Diodes

Many junction boxes contain bypass diodes, which are semi-conductor devices that allow current to flow in only one direction. Bypass diodes help to prevent hot spots and minimize power losses in cases where some solar cells or strings are shaded or malfunctioning.

Protection

The junction box provides protection for the internal wiring and electrical connections from environmental factors such as dust, debris, and temperature fluctuations.

Conclusion

With the basic components listed above, a solar is made to work and produce electricity for use. Without any of the above components, a solar panel does not perform its work. All the solar panel manufacturers first prepare these components and then start combining them in the form of a solar panel. We hope this article might be very helpful to you. If yes, let us know in comments.